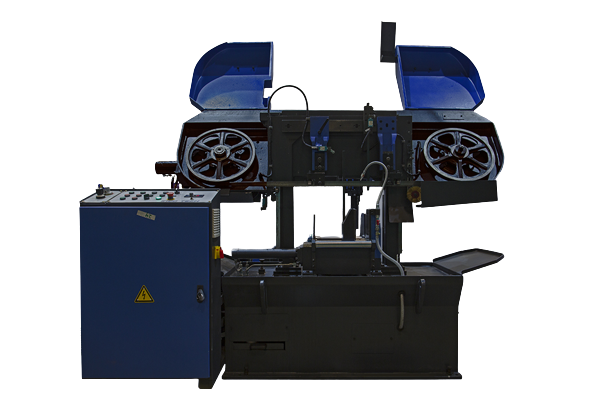

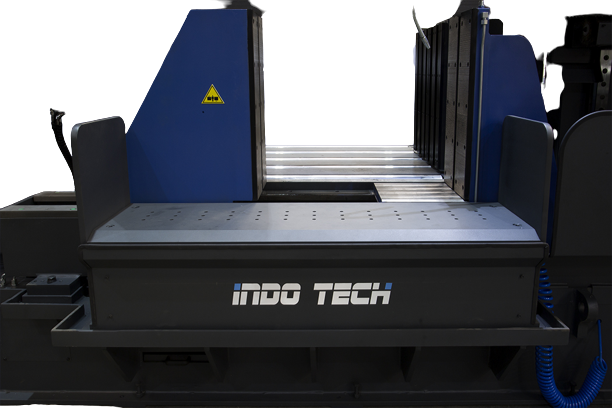

ITM-210 LMGA

Saw band dimensions:

4000 x 27 x 0.9 mm

Cutting capacity:

Ø210mm ▢210 x 210mm

Categories: Horizontal cutting bandsaws series, Tough line

High Quality High Rigidity High Efficiency

ITM-210 LMGA

Saw band dimensions:

4000 x 27 x 0.9 mm

Cutting capacity:

Ø210mm ▢210 x 210mm

Features of ITM-210 LMGA

High Efficiency Power Transmission to Saw thru HELICAL GEARED MOTOR.

Saw Frame movement on Pre-hardened and Pre-loaded LM guides for friction free movement.

Cycle sequencing thru PLC and user friendly Touch Screen for easy operation.

Special bearing housing with heavy duty Cylindrical Roller bearing to isolate the Gear box from the load of blade tensioning.

Specially designed pressure valve to accurately balance the saw frame during cutting operation depending on material being cut thereby resulting in much better tool life.

NC Version – Length setting thru Digital Linear scale alongwith Sensor with Multiple Batch programming thru High End PLC with frequency convertor. Length to be set thru PLC without any Human intervention.

Powerised wire brush unit.

A.C. frequency control drive for infinite variation of band speed thru control panel.

Hydraulic Floating Shuttle Vice for uneven Bars.

Bar exhaust control unit.

Double Acting Hydraulic Cylinder for Main Vice and Shuttle Vice.

State of art Manual Blade Tensioning.

Infinitely variable Feed Control Valve for Setting the Cutting Rate.

Auto indexing shuttle of stroke length of 500 mm (With Bundle Cutting 400mm) and synchronized with auto cycle.

Adjustable & Movable Dovetail type Heavy duty Movable Blade guide.

Separate Hydraulic Power Pack for easy maintenance with a tank of 80 Ltr.

Ergonomically designed Electrical Control Panel.

Automatic Machine OFF, in case of Blade Breakage.

Technical Data ITM-210 LMGA

High Efficiency Power Transmission to Saw thru HELICAL GEARED MOTOR.

Saw Frame movement on Pre-hardened and Pre-loaded LM guides for friction free movement.

Cycle sequencing thru PLC and user friendly Touch Screen for easy operation.

Special bearing housing with heavy duty Cylindrical Roller bearing to isolate the Gear box from the load of blade tensioning.

Specially designed pressure valve to accurately balance the saw frame during cutting operation depending on material being cut thereby resulting in much better tool life.

NC Version – Length setting thru Digital Linear scale alongwith Sensor with Multiple Batch programming thru High End PLC with frequency convertor. Length to be set thru PLC without any Human intervention.

Powerised wire brush unit.

A.C. frequency control drive for infinite variation of band speed thru control panel.

Hydraulic Floating Shuttle Vice for uneven Bars.

Bar exhaust control unit.

Double Acting Hydraulic Cylinder for Main Vice and Shuttle Vice.

State of art Manual Blade Tensioning.

Infinitely variable Feed Control Valve for Setting the Cutting Rate.

Auto indexing shuttle of stroke length of 500 mm (With Bundle Cutting 400mm) and synchronized with auto cycle.

Adjustable & Movable Dovetail type Heavy duty Movable Blade guide.

Separate Hydraulic Power Pack for easy maintenance with a tank of 80 Ltr.

Ergonomically designed Electrical Control Panel.

Automatic Machine OFF, in case of Blade Breakage.

| Machine dimensions | ||||||

| Length | 2400 mm | |||||

| Width | 1700 mm | |||||

| Height | 1500 mm | |||||

| Machine electrical equipment | ||||||

| Supply voltage | ~3 x 415V, 50Hz | |||||

| Protection degree | IP 54 | |||||

| Driving engine of the saw band | ||||||

| Type | ~ 3 x 415V, 50Hz | |||||

| Output | 3.0 HP | |||||

| Hydraulic and Coolant motor | ||||||

| Coolant motor | 0.16HP | |||||

| Hydraulic motor | 1.0HP | |||||

| Saw band dimensions | ||||||

| 4000 x 27 x 0.9 mm | ||||||

| Cutting Capacity | ||||||

| Ø300 mm | Ø300 mm | 300 x 300 mm | 300 x 300 mm | |||

LengthWidthHeight | 2400 mm1700 mm1500 mm |

Supply voltageProtection degree | ~3 x 415V, 50HzIP 54 |

TypeOutput | ~ 3 x 415V, 50Hz3.0 HP |

Coolant motorHydraulic motor | 0.16 HP1.0 HP |

4000 x 27 x 0.9 mm |

| Ø210mm | Ø210mm | 210 x 210mm | 210 x 210mm |

Productos relacionados

-

ITM-850 LMGA (RF)

Valorado en 0 de 5Leer más -

ITM-650 LMGS

Valorado en 0 de 5Leer más -

ITM-650 LMGA (RF)

Valorado en 0 de 5Leer más -

ITM-460 LMGS

Valorado en 0 de 5Leer más

Personal service

Do you have questions about our product range or do you need technical advice?