Facilitating precision

Metal cutting

Infraestructure

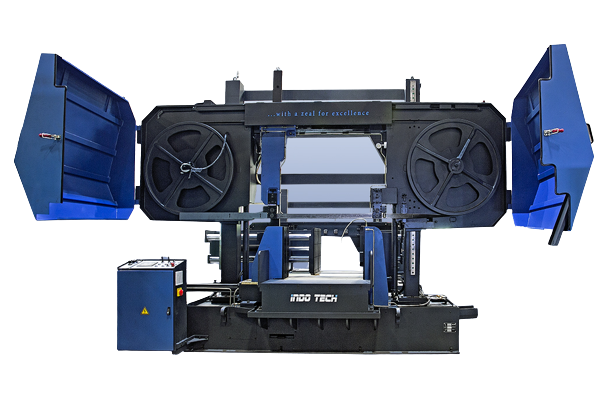

The advanced manufacturing facilty at INDOTECH plant is the hub for manufacturing a range of quality Metal Cutting solutions. With the help of a discerning people force, cutting-edge technology, and value-added services, we are able to deliver unmatched standards of product quality to our customers.

The state-of-the-art manufacturing, process control instrumentation and robust quality control system – all have contributed to a positive reputation the company enjoys amongst a host of clients worldwide.

The spark of

Excellence

Machines delivered

Global Locations

Satisfied Clients

Years of Experience

With a vision to bring world class metal cutting solutions and services to the world, INDOTECH continues delivers robust and cutting edge solutions across various verticals of the engineering industry.

With an in-depth experience in Metal Cutting Industry spanning three decades, with several milestones to our credit, INDOTECH is recognised as reliable end-to-end solution provider for the industry. Today we serve a long list of blue-chip industries with more than 68% of revenue from our existing customers, speaks volumes about our quality deliveries.

A foresight spanning decades with focus on the future

INDOTECH combines the age old insustry know-how with the modern soluion-based approach of a global player. Today, our customer base comprises of a wide spectrum companies – right from automobile industries and their ancillaries, general mechanical engineering, energy, aerospace, defence, oil and gas, R&D to name a few.

Machines delivered

Global Locations

Satisfied Clients

Years of Experience

Engineering

To create value

Quality at

The Core

Our vision is to reach out to enterprising corporations in need of quality machines and tools globally by providing high quality affordable products. To foster this, we have always head our eyes set on meeting the demands of world class product delivery.

To this effect, INDOTECH manufacturing facilities have been going through extensive upgrades from time to time to meet the criterion of modern machine manufacturing plants.

A sound and consistent knowledge based on a deep understanding of the industry allows us to simplify our clients needs and make way for flawless products. To further warrant this, the R&D department at INDOTECH works in close association with out customers for quality delivery.

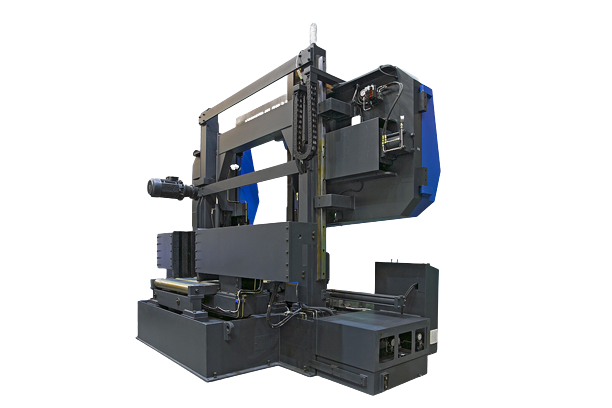

Our innovative bandsaw machines and machining systems along with modern production engineering and high vertical integration provides optimum control of every single component of our machines. A slew of stringent quality measures ensures each product goes through a meticulous performance check. All these endeavours help us in delivering world class bespoke solutions in machineries.

Precision

From the heart

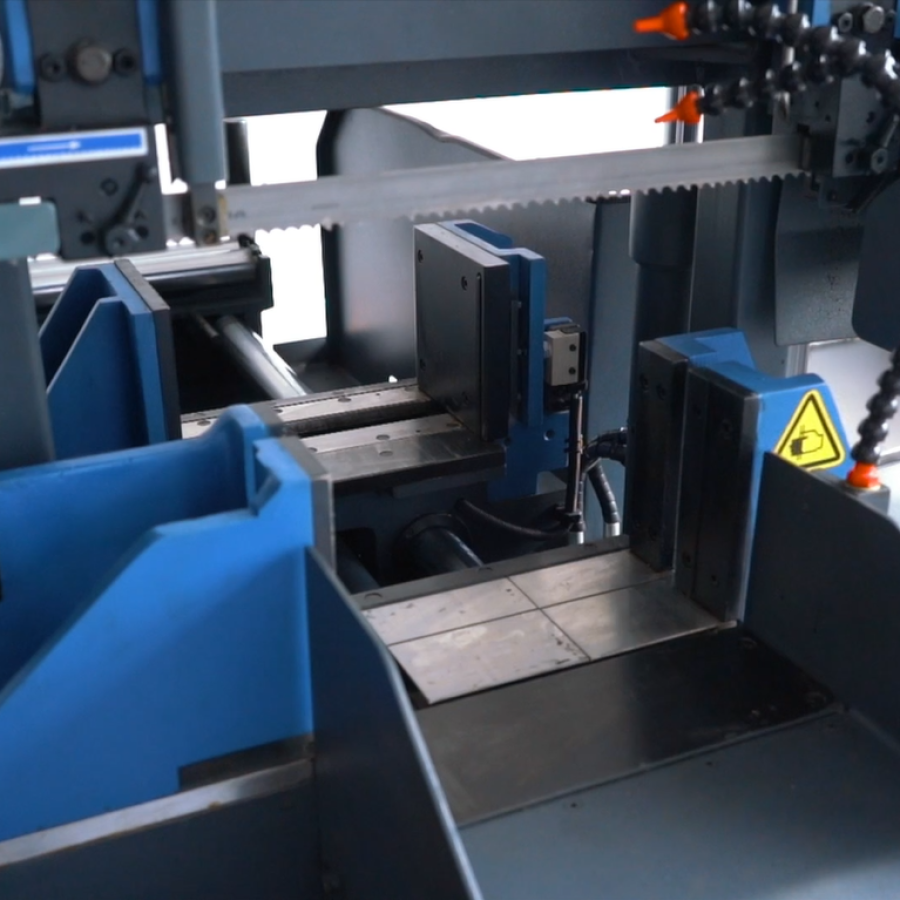

Automatic Blade Tensioning

POWER TRANSMISSION

BLADE GUIDING

BEARING HOUSING

Pressure Valve

Auto indexing shuttle

Additional Wheel Support

Cycle Sequencing

Cycle sequencing through PLC and user friendly touch screen for easy operationNumerically Controlled version for Length Setting

Best in class

Metal cutting solutions

Find the right machine for your requirements

Indotech offers an extended range of solutions to achieve increased productivity and flexibility in production based in your requirements. These machines are designed for stable processes in harsh daily production environments and components are adequately tested, ensuring robust machines for optimum utilization.